Vulcan

Capability.

Partnership.

Value.

AMERICA'S ROCKET.

ONE SYSTEM FOR ALL MISSIONS.

Transformed to meet our customer's needs, our cost has dropped considerably to provide the best value choice.

Will provide higher performance and greater accessibility while continuing to deliver our unmatched reliability and precision.

Flight-proven design, coupled with innovative technology, will transform the future of space launch.

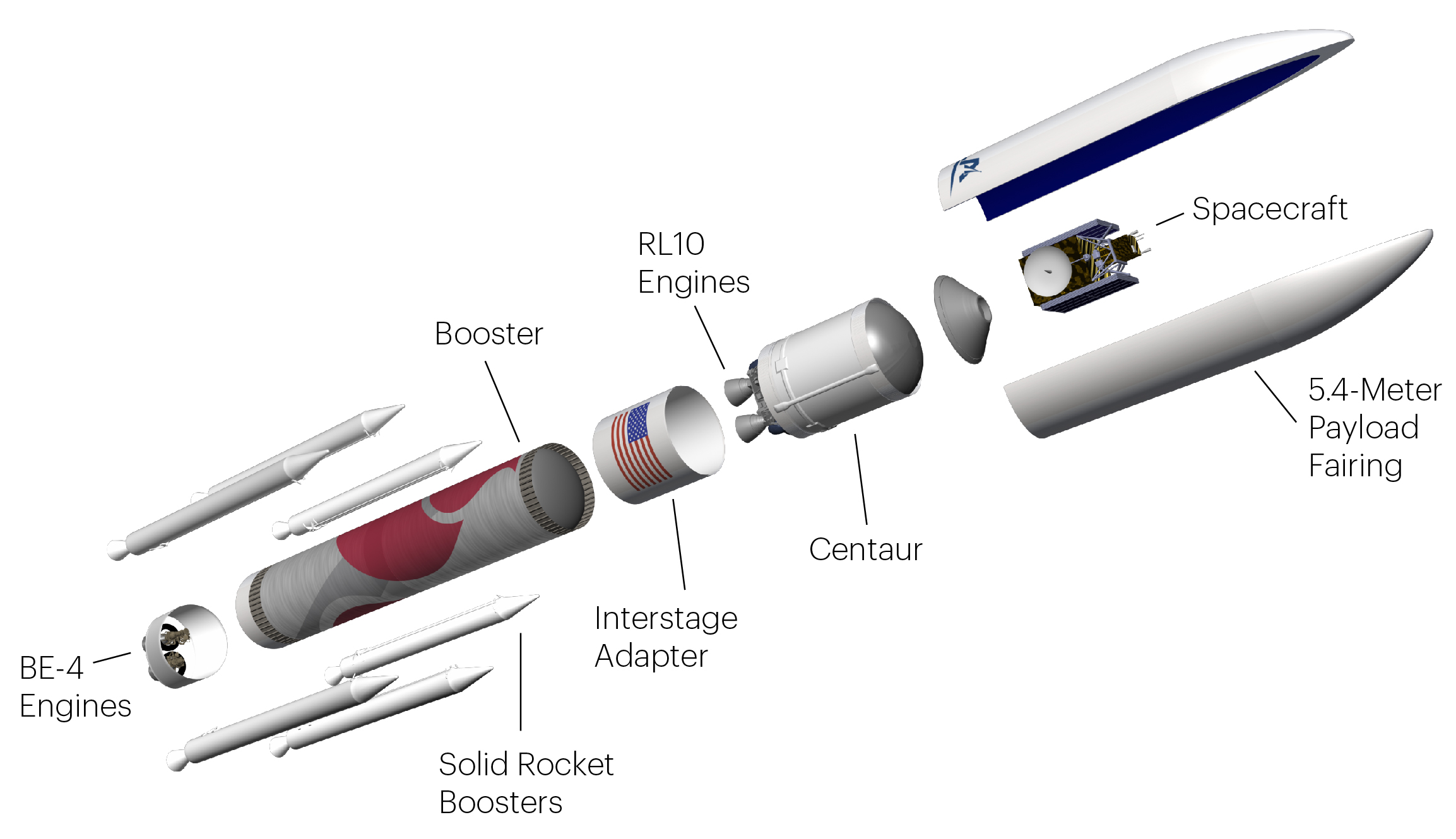

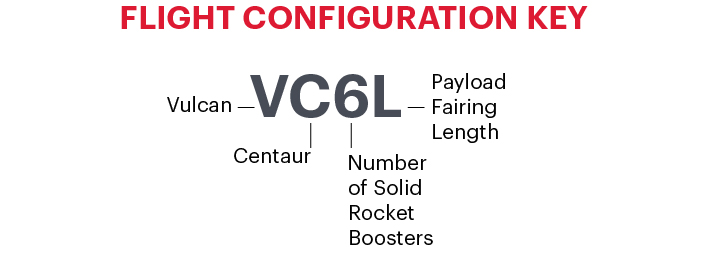

CONFIGURATIONS

Vulcan is available in four standard offering configurations including zero, two, four and six solid rocket booster (SRB) variants.

PERFORMANCE

Optimal orbit for each customer, delivering industry best spacecraft orbital insertion accuracy.

GEO | GTO | LEO-REF | LEO-ISS | LEO-POLAR | MEO | TLI | |

0 Solids | N/A | 3,500 kg | 10,800 kg | 9,200 kg | 8,500 kg 18,700 lbs | N/A

| 2,300 kg 5,100 lbs |

2 Solids | 2,600 kg | 8,400 kg | 19,000 kg | 16,300 kg | 15,200 kg | 3,900 kg 8,600 lbs | 6,300 kg 13,900 lbs |

4 Solids | 4,900 kg | 11,700 kg | 24,600 kg | 21,600 kg | 20,000 kg | 6,200 kg 13,700 lbs | 9,200 kg 20,300 lbs |

6 Solids | 6,500 kg | 14,500 kg | 27,200 kg | 25,800 kg | 23,900 kg | 8,100 kg 17,900 lbs | 11,500 kg 25,400 lbs |

Upgrade | 7,000 kg | 15,300 kg | 27,200 kg | 26,900 kg | 24,900 kg | 8,600 kg 19,000 lbs | 12,100 kg 26,700 lbs |

GEO (Geosynchronous Earth Orbit) = 35,786 km circular at 0 deg

GTO (Geosynchronous Transfer Orbit) = 35,786 km x 185 km at 27.0 deg

LEO-Reference (Low Earth Orbit-Reference) = 200 km circular at 28.7 deg

LEO-ISS (Low Earth Orbit-International

Space Station) = 407 km circular at 51.6 deg

LEO-Polar (Low Earth Orbit-Polar) = 200 km circular at 90 deg

MEO (Medium Earth Orbit) = 20,368 km circular at 55 deg

TLI (Trans-lunar Injection) = C3: -2 km2/sec2

Example: Peregrine will fly on a VC2S, Dream Chaser will fly on a VC4L

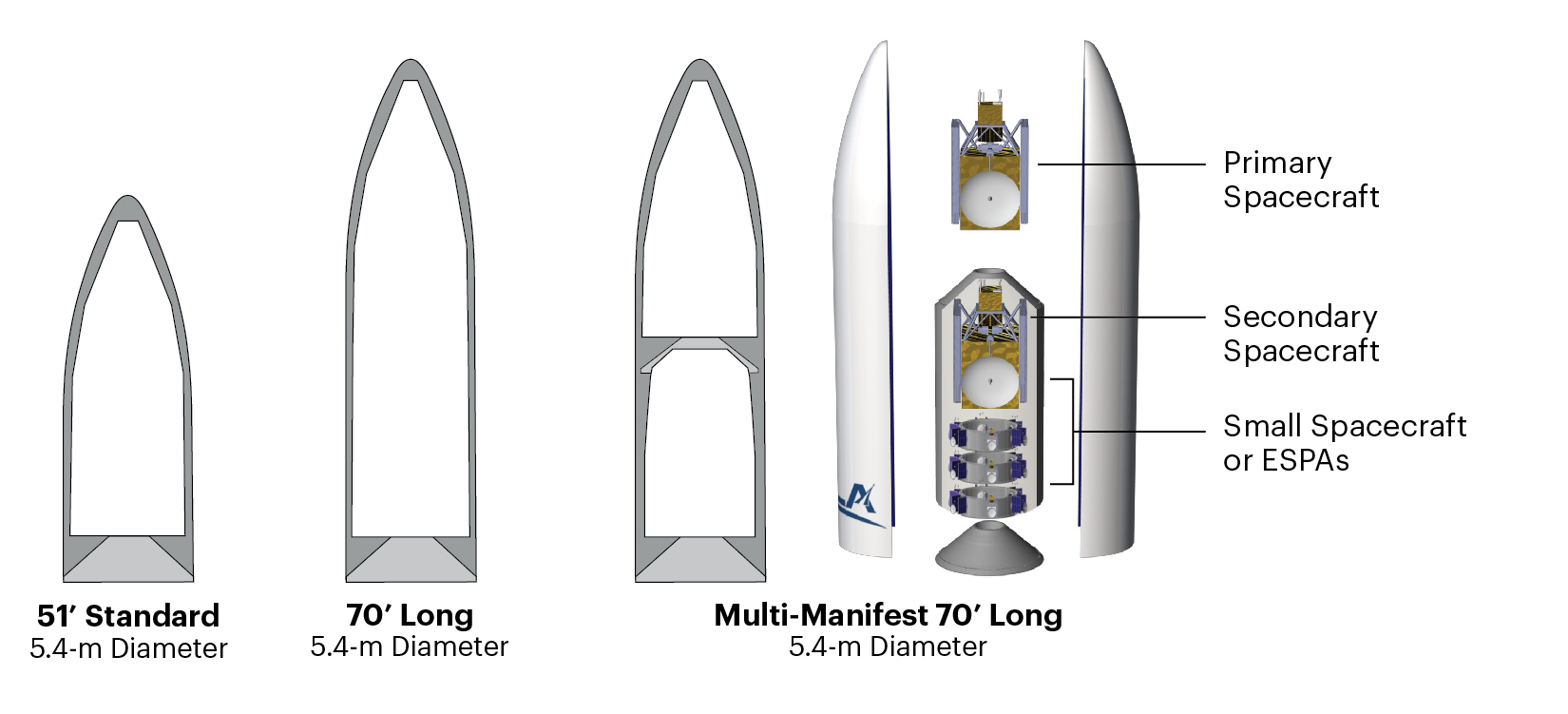

PAYLOAD FAIRINGS

The payload fairing (PLF) provides a controlled, safe environment for spacecraft during ascent. All ULA PLFs are configured for off-pad payload encapsulation to enhance payload safety and security and minimize on-pad time.

The spacecraft is

encapsulated in a 5.4-m- (17.7-ft-) diameter payload fairing (PLF), a sandwich composite structure made with a vented aluminum-honeycomb core and graphite-epoxy face sheets. The bisector (two-piece shell) PLF encapsulates the spacecraft. The payload

attach fitting (PAF) is a similar sandwich composite structure creating the mating interface from spacecraft to second stage and payload fairing. The PLF separates using a debris-free horizontal and vertical separation system with spring packs and

frangible joint assembly. The payload fairing is available in the 15.5-m (51-ft) standard and 21.3-m (70-ft) long configurations.

Multi-Manifest

Access to orbit remains a critical hurdle for many missions. However, ULA provides flexible and cost-effective multi-manifest solutions to overcome this barrier. With multi-manifest, two or more spacecraft are integrated on a launch vehicle using available performance and volume margin that would otherwise go unused — optimizing mass to orbit and enabling missions. Multi-Manifest on a Vulcan rocket provides a highly reliable and schedule certain launch solution for spacecraft ranging from CubeSats to small sats and beyond.

Dependent on the size of the spacecraft, multi-manifesting on a Vulcan can be done in several ways. The Aft Bulkhead Carrier (ABC) interfaces at the aft end of the Centaur upper stage and can carry up to 24U CubeSats weighing 80 kg each. The Secondary Payload Adapter (ESPA Ring) is located between the upper stage and the primary payload and can accommodate 4-6 payload modules weighing up to 318 kg each. Finally, for small satellites exceeding the mass of an ESPA capability, the Multi-Payload Canister System is a load-bearing separating canister that can be utilized to enclose an aft small satellite while supporting a forward traditional large satellite.

PROPULSION

Main Engine

Booster propulsion is provided by a pair of BE-4 engines, manufactured by Blue Origin.

Nominal Thrust (sea level): 550,000 lbs

Fuel/Oxidizer: Liquefied Natural Gas (LNG)/Liquid Oxygen (LO2)

Solid Rocket Boosters

Vulcan integrates up to six Northrop Grumman Graphite Epoxy Motor (GEM) 63XL Solid Rocket Boosters (SRBs). They are constructed out of a graphite-epoxy composite with the throttle profile designed into the propellant grain. GEM solids supported

the Delta II and Delta IV rockets, and the GEM 63 variant will fly on ULA’s Atlas V rocket prior to the first Vulcan launch.

Peak Vacuum Thrust: 459,600 lbs

Length: 71.8 ft

Nominal Burn Time: 90 seconds

Upper Stage

Vulcan will rely on two RL10C engines to power its second stage. Logging an impressive record of nearly 400 successful flights and nearly 700 firings in space, RL10 engines, manufactured by Aerojet Rocketdyne, harness the power of high-energy

liquid hydrogen. The RL10 boasts a precision control system and restart capability to accurately place payloads into orbit.

Nominal Thrust: 24,000 lbs

Fuel/Oxidizer: Liquid Hydrogen/Liquid Oxygen

INFRASTRUCTURE UPDATES

ULA has been heavily investing in modifying our factory in Decatur, Alabama, and modernize our infrastructure at the launch facilities in Cape Canaveral, Florida, to support Vulcan rockets. Space Launch Complex-41 (SLC-41) will be the first dual-use

pad launching both Atlas V and Vulcan rocket families.

Decatur, Alabama Factory

- New automated tooling solution for 5.4-meter-diameter Centaur V

- Universal weld system and welding equipment upgrades

- Robotic assembly line for tank fabrication

- New tooling for integration, testing and checkout

- Additional modernization for maximum efficiency and reliability

Cape Canaveral, Florida Launch Facilities

- Upgraded Vertical Integration Facility (VIF) platforms, decks and crane to accommodate all Atlas and Vulcan configurations

- Modifications to SLC-41 to accommodate Vulcan processing and launch:

- Liquefied natural gas (LNG) ground systems

- Increasing the fuel and oxidizer storage capacity

- Increasing acoustic water suppression system capacity

- Upgraded former solid rocket assembly facility, now known as Spaceflight Processing Operations Center (SPOC), to accommodate Vulcan Launch Platform (VLP) construction and storage

- Renovated the rail system from SLC-41 to the SPOC to accommodate Mobile Launch Platform (MLP)/VLP transport and overlapping Vulcan and Atlas

launch campaigns - Additional modernization for maximum efficiency and reliability